The plant hormone methyl jasmonate can be used to increase broccoli’s antitumoral properties

http://www.chemistryviews.org/details/news/5428251/Boosting_Broccoli_Power.html

back to home for more updates

![]()

DR ANTHONY MELVIN CRASTO Ph.D

The plant hormone methyl jasmonate can be used to increase broccoli’s antitumoral properties

http://www.chemistryviews.org/details/news/5428251/Boosting_Broccoli_Power.html

back to home for more updates

![]()

DR ANTHONY MELVIN CRASTO Ph.D

(NaturalNews) Various cultures around the world already understand that herbs such as ginger, cinnamon, garlic and turmeric can effectively treat conditions like diabetes. According to research from the biomedical science department at the King Faisal University in Saudi Arabia, garlic may be the most powerful of them all for treating diabetes.

Learn more: http://www.naturalnews.com/042941_garlic_diabetes_treatment_oxidative_stress.html##ixzz2l5NBhJ00

Vitamin D is an essential vitamin required by the body for the proper absorption of calcium, bone development, control of cell growth, neuromuscular functioning, proper immune functioning, and alleviation of inflammation. A deficiency in vitamin D can lead to rickets, a disease in which bones fail to properly develop. Further, inadequate levels of vitamin D can lead to a weakened immune system, increased cancer risk, poor hair growth, and osteomalacia, a condition of weakened muscles and bones. Conversely, excess vitamin D can cause the body to absorb too much calcium, leading to increased risk of heart attack and kidney stones. The current U.S. DV for vitamin D is 600 IU (international units) and the toxicity threshold for vitamin D is thought to be 10,000 to 40,000 IU/day.2 Vitamin D is oil soluble, which means you need to eat fat to absorb it. It is naturally found mainly in fish oils, fatty fish, and to a lesser extent in beef liver, cheese, egg yolks, and certain mushrooms. Vitamin D is also naturally made by your body when you expose your skin to the sun, and thus, is called the sun-shine vitamin. In addition, vitamin D is widely added to many foods such as milk and orange juice, and can also simply be consumed as a supplement. Below is a list of high vitamin D foods.

1: Cod Liver Oil

Cod liver oil has been a popular supplement for many years and naturally contains very high levels of vitamin A and vitamin D. Cod liver oil provides 10001IU (1667% DV) per 100 gram serving, or 1360IU (340% DV) in a single tablespoon.

Cod liver oil has been a popular supplement for many years and naturally contains very high levels of vitamin A and vitamin D. Cod liver oil provides 10001IU (1667% DV) per 100 gram serving, or 1360IU (340% DV) in a single tablespoon.

2: Fish

Various types of fish are high in vitamin D. Typically raw fish contains more vitamin D than cooked, and fatty cuts will contain more than lean cuts. Further, fish canned in oil will have more vitamin D than those canned in water. Raw fish is typically eaten in the form of sushi. Raw Atlantic Herring provides the most vitamin D with 1628IU (271% DV) per 100 gram serving, 2996IU (499% DV) per fillet, and 456IU (76% DV) per ounce. It is followed by Pickled Herring with 680IU (113% DV) per 100g serving, Canned Salmon (127% DV), Raw Mackerel (60% DV), Oil Packed Sardines (45% DV), Canned Mackerel (42% DV), and oil packed Tuna (39% DV).

Various types of fish are high in vitamin D. Typically raw fish contains more vitamin D than cooked, and fatty cuts will contain more than lean cuts. Further, fish canned in oil will have more vitamin D than those canned in water. Raw fish is typically eaten in the form of sushi. Raw Atlantic Herring provides the most vitamin D with 1628IU (271% DV) per 100 gram serving, 2996IU (499% DV) per fillet, and 456IU (76% DV) per ounce. It is followed by Pickled Herring with 680IU (113% DV) per 100g serving, Canned Salmon (127% DV), Raw Mackerel (60% DV), Oil Packed Sardines (45% DV), Canned Mackerel (42% DV), and oil packed Tuna (39% DV).

3: Fortified Cereals

4: Oysters

In addition to vitamin D, Oysters are a great source of vitamin b12, zinc, iron, manganese, selenium, and copper. Oysters are also high in cholesterol and should be eaten in moderation by people at risk of heart disease or stroke. Raw wild caught Eastern Oysters provide 320IU (80% DV) per 100 gram serving, 269IU (67% DV) in six medium oysters.

In addition to vitamin D, Oysters are a great source of vitamin b12, zinc, iron, manganese, selenium, and copper. Oysters are also high in cholesterol and should be eaten in moderation by people at risk of heart disease or stroke. Raw wild caught Eastern Oysters provide 320IU (80% DV) per 100 gram serving, 269IU (67% DV) in six medium oysters.

5: Caviar (Black and Red)

Caviar is a common ingredient in sushi and more affordable than people think. Caviar provides 232IU (58% DV) of vitamin D per 100 gram serving, or 37.1IU (9% DV) per teaspoon.

Caviar is a common ingredient in sushi and more affordable than people think. Caviar provides 232IU (58% DV) of vitamin D per 100 gram serving, or 37.1IU (9% DV) per teaspoon.

6: Fortified Soy Products (Tofu and Soy Milk)

Fortified soy products are often fortified with both vitamin D and calcium. Fortified Tofu can provide up to 157IU (39% DV) of vitamin D per 100 gram serving, or 44IU (11% DV) per ounce. Fortified Soy Milk can provide up to 49IU (12% DV) of vitamin D per 100 gram serving, 119IU (30% DV) per cup. Amounts of vitamin D vary widely between products, so be sure to check nutrition facts for vitamin D content.

Fortified soy products are often fortified with both vitamin D and calcium. Fortified Tofu can provide up to 157IU (39% DV) of vitamin D per 100 gram serving, or 44IU (11% DV) per ounce. Fortified Soy Milk can provide up to 49IU (12% DV) of vitamin D per 100 gram serving, 119IU (30% DV) per cup. Amounts of vitamin D vary widely between products, so be sure to check nutrition facts for vitamin D content.

7: Salami, Ham, and Sausages

Salami, Ham, and Sausages are a good source of vitamin b12, and copper. Unfortunately, they are also high in cholesterol and sodium, and so should be limited by people at risk of hypertension, heart attack, and stroke. Salami provides 62.0IU (16% DV) of vitamin D per 100 gram serving, or 16.7IU (4% DV) per ounce (3 slices). It is followed by Bologna Pork 56IU (9% DV) per 100 grams, and Bratwurst 44IU (7% DV) per 100 gram serving.

Salami, Ham, and Sausages are a good source of vitamin b12, and copper. Unfortunately, they are also high in cholesterol and sodium, and so should be limited by people at risk of hypertension, heart attack, and stroke. Salami provides 62.0IU (16% DV) of vitamin D per 100 gram serving, or 16.7IU (4% DV) per ounce (3 slices). It is followed by Bologna Pork 56IU (9% DV) per 100 grams, and Bratwurst 44IU (7% DV) per 100 gram serving.

8: Fortified Dairy Products

Dairy products are already high in calcium, so it makes sense to fortify them with vitamin D. Milk can provide up to 52.0IU (13% DV) of vitamin D per 100 gram serving, 127IU (32% DV) per cup. Cheese can provide up to 6.6IU (2% DV) in a cubic inch, and butter provides 7.8IU (2% DV) in a single tablespoon. Check nutrition labels for exact amounts.

Dairy products are already high in calcium, so it makes sense to fortify them with vitamin D. Milk can provide up to 52.0IU (13% DV) of vitamin D per 100 gram serving, 127IU (32% DV) per cup. Cheese can provide up to 6.6IU (2% DV) in a cubic inch, and butter provides 7.8IU (2% DV) in a single tablespoon. Check nutrition labels for exact amounts.

9: Eggs

In addition to vitamin D, eggs are a good source of vitamin B12, and protein. Eggs provide 37.0IU (9% DV) of vitamin D per 100 gram serving, or 17.0IU (4% DV) in a large fried egg.

In addition to vitamin D, eggs are a good source of vitamin B12, and protein. Eggs provide 37.0IU (9% DV) of vitamin D per 100 gram serving, or 17.0IU (4% DV) in a large fried egg.

10: Mushrooms

More than just a high vitamin D food, mushrooms also provide Vitamin B5 (Pantothenic Acid) and copper. Lightly cooked white button mushrooms provide the most vitamin D with 27.0IU (7% DV) per 100 gram serving, or 7.6IU (2% DV) per ounce.

More than just a high vitamin D food, mushrooms also provide Vitamin B5 (Pantothenic Acid) and copper. Lightly cooked white button mushrooms provide the most vitamin D with 27.0IU (7% DV) per 100 gram serving, or 7.6IU (2% DV) per ounce.

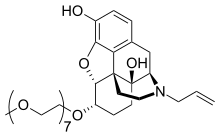

naloxegol

Morphinan-3,14-diol, 4,5-epoxy-6-(3,6,9,12,15,18,21-heptaoxadocos-1-yloxy)-17-(2-

propen-1-yl)-, (5α,6α)-

2. 4,5α-epoxy-6α-[(3,6,9,12,15,18,21-heptaoxadocosan-1-yl)oxy]-17-(prop-2-en-1-

yl)morphinan-3,14-diol

http://www.ama-assn.org/resources/doc/usan/naloxegol.pdf

MOLECULAR FORMULA C34H53NO11

MOLECULAR WEIGHT 651.8

SPONSOR AstraZeneca

CODE DESIGNATION NKTR-118

CAS REGISTRY NUMBER 854601-70-0

The US Food and Drug Administration (FDA) has accepted AstraZeneca’s new drug application (NDA) for naloxegol, an investigational peripherally acting mu-opioid receptor antagonist (PAMORA) for the treatment of opioid-induced constipation (OIC).

read at

FDA accepts AstraZeneca’s new drug application for constipation drug

Naloxegol (INN; NKTR-118), or PEGylated naloxol,[1] is a peripherally-selective opioid antagonist under development by AstraZeneca, licensed from Nektar, for the treatment of opioid-induced constipation.[2]

NALOXEGOL OXALATE

credit kegg

NALOXEGOL OXALATE

http://www.ama-assn.org/resources/doc/usan/naloxegol-oxalate.pdf

Morphinan-3,14-diol, 4,5-epoxy-6-(3,6,9,12,15,18,21-heptaoxadocos-1-yloxy)-

17-(2-propen-1-yl)-, (5α,6α)-, ethanedioate (1:1)

2. 4,5α-epoxy-6α-[(3,6,7,12,15,18,21-heptaoxadocosyl)oxy]-17-(prop-2-

enyl)morphinan-3,14-diol hydrogen ethanedioate

MOLECULAR FORMULA C34H53NO11 . C2H2O4

MOLECULAR WEIGHT 741.8

SPONSOR AstraZeneca

CODE DESIGNATIONS NKTR-118 oxalate, AZ13337019 oxalate

CAS REGISTRY NUMBER 1354744-91-4

About Opioid-Induced Constipation

Opioids are commonly prescribed to patients experiencing chronic pain, which can provide relief from serious medical conditions including osteoarthritis, cancer, and chronic back pain.1 There are about 250 million opioid prescriptions written annually in the US alone to treat these conditions.2 Patients taking opioids to treat chronic pain commonly experience a side effect known as opioid-induced constipation, which may include infrequent bowel movements and difficulty passing stools or emptying bowels.1,3 Clinically, OIC is the most prevalent side effect of opioid therapy.4 For those patients who take opiates for long term pain management, approximately 40-50 percent commonly experience OIC.5 Only about 40-50 percent of those patients experience effective relief from current treatment options.6,7

About Naloxegol (NKTR-118)

Naloxegol (NKTR-118) is an investigational drug candidate in Phase 3 studies being developed as a once-daily oral tablet for the treatment of opioid-induced constipation. Naloxegol (NKTR-118) was designed using Nektar’s proprietary small molecule polymer conjugate technology. Results of the Phase 2 study of naloxegol (NKTR-118) were presented in October 2009 at the American College of Gastroenterology Annual Clinical Meeting and the American Academy of Pain Management. NKTR-119 is an early stage drug development program that is intended to combine oral naloxegol (NKTR-118) with selected opioids, with the goal of treating pain without the side effect of constipation traditionally associated with opioid therapy.

Nektar and AstraZeneca have a global agreement for both naloxegol (NKTR-118) and NKTR-119. Under the agreement, AstraZeneca has responsibility for the development, global manufacturing and marketing of both naloxegol (NKTR-118) and NKTR-119. For naloxegol (NKTR-118), Nektar is eligible to receive up to $235 million in aggregate payments upon the achievement of certain regulatory milestones, as well as additional tiered sales milestone payments of up to $375 million if the product achieves considerable levels of commercial success. Nektar will also be eligible to receive significant double-digit royalty payments on net sales of naloxegol (NKTR-118) worldwide. For NKTR-119, Nektar would receive development milestone payments as well as tiered sales milestone payments. Nektar will also receive significant double-digit royalty payments on NKTR-119 net sales worldwide.

| The AstraZeneca Phase 3 KODIAC Program for Naloxegol (NKTR-118) The KODIAC Program consists of two randomized, placebo controlled Phase III efficacy studies and an open-label, randomized, placebo-controlled long term safety study. The two efficacy studies are identical with 12-week treatment periods. These studies are intended to evaluate the efficacy, safety and tolerability of an AstraZeneca investigational drug in patients with OIC. KODIAC is part of the KODIAC program of studies looking to determine whether naloxegol (NKTR-118) is safe and effective for the treatment of constipation seen as a side effect in people taking prescription opioid pain medications. AstraZeneca plans the first regulatory filings based on the program in 2013. |

References

http://newdrugapprovals.wordpress.com/2013/09/28/ema-accepts-astrazenecas-naloxegol-application/

DAGLUTRIL, SLV306

phase 2

Daglutril is a novel dual-action endopeptidase inhibitor which had been in phase II clinical development by Solvay for the treatment of hypertension, congestive heart failure (CHF) and pulmonary hypertension; however, no recent development has been reported for this research.

Daglutril inhibits NEP (neutral endopeptidase) and ECE (endothelin-converting enzyme) and thereby exerts vasodilating, blood pressure-lowering and other potentially beneficial effects on the cardiovascular system.

| 2-[3(S)-[1-[2(R)-(Ethoxycarbonyl)-4-phenylbutyl]cyclopentan-1-ylcarboxamido]-2-oxo-2,3,4,5-tetrahydro-1H-1-benzazepin-1-yl]acetic acid | |

| cas | 182821-27-8, 182560-84-5 (undefined stereochem.) |

| C31H38N2O6 | |

| mw | 534.6492 |

| Cardiovascular Drugs, Heart Failure Therapy, Hypertension, Treatment of, Endothelin-Converting Enzyme Inhibitors, Neprilysin Inhibitors |

SOLWAY

Neprilysin (Enkephalinase, Neutral Endopeptidase, NEP) Inhibitors

Endothelin-Converting Enzyme (ECE) Inhibitors

182821-27-8, 1H-1-Benzazepine-1-acetic acid, 3-(((1-(2-(ethoxycarbonyl)-4-phenylbutyl)cyclopentyl)carbonyl)amino)-2,3,4,5-tetrahydro-2-oxo-, (S-(R*,S*))-, 1H-1-Benzazepine-1-acetic acid, 3-(((1-((2R)-2-(ethoxycarbonyl)-4-phenylbutyl)cyclopentyl)carbonyl)amino)-2,3,4,5-tetrahydro-2-oxo-, (3S)-, 2-[(3S)-3-[[1-[(2R)-2-carbethoxy-4-phenyl-butyl]cyclopentanecarbonyl]amino]-2-keto-4,5-dihydro-3H-1-benzazepin-1-yl]acetic acid,

The acylation of the chiral amine (I) with the chiral cyclopentanecarboxylic aid (II) by means of N-methylmorphline (NMM), hydroxybenzotriazole (HOBT) and N-(dimethylaminopropyl)-N’-ethylcarbodiimide (EDT) in dichloromethane gives the amide (III), which is then treated with trifluoroacetic acid to elimnate the tert-butyl ester groups.

| Benzazepin-, benzoxazepin- and benzothiazepin-N-acetic acid-derivs., their preparation and their pharmaceutical compsns. | |

| Waldeck, H.; ET AL (Kali-Chemie AG) | |

| CA 2172354; EP 0733642; JP 1996269011; US 5677297 | |

|

|

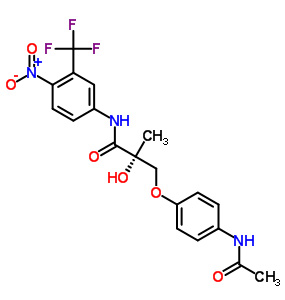

(SARM-4, S-4), GTx-007

Acetamidoxolutamide

Androxolutamide

401900-40-1

WO 2002016310

Selective Androgen Receptor Modulators (SARM)

Signal Transduction Modulators

Andarine (GTx-007, S-4) is an investigational selective androgen receptor modulator (SARM) developed by GTX, Inc for treatment of conditions such as muscle wasting, osteoporosis and benign prostatic hypertrophy, using the non-steroidal androgen antagonist bicalutamide as a lead compound.

Androxolutamide is a nonsteroidal selective androgen receptor modulator (SARM) which had been in early clinical trials at GTx for the treatment of cancer-related cachexia in several cancer types; however, no recent development has been reported for this indication. Preclinical studies had also been ongoing for the treatment of osteoporosis due to androgen deficiency in the aging male. The drug candidate is believed to bind to the testosterone receptor in such a way as to maximize the beneficial effects of the hormone like muscle growth, bone strengthening and enhanced libido, while minimizing the unwanted side effects, such as stimulation of prostate cancer, virilization and acne. This is accomplished by the selective modulation of the androgen receptor depending on tissue type.

The compound was originally developed at GTx. In March 2004, GTx entered into a joint collaboration and license agreement with Ortho Biotech, a wholly-owned subsidiary of Johnson & Johnson; however, in 2006 the agreement was terminated by mutual agreement of the companies.

Andarine is an orally active partial agonist for androgen receptors. It is less potent in both anabolic and androgenic effects than other SARMs. In an animal model of benign prostatic hypertrophy, andarine was shown to reduce prostate weight with similar efficacy to finasteride, but without producing any reduction in muscle mass or anti-androgenic side effects. This suggests that it is able to competitively block binding of dihydrotestosterone to its receptor targets in the prostate gland, but its partial agonist effects at androgen receptors prevent the side effects associated with the anti-androgenic drugs traditionally used for treatment of BPH

Family: Selective Androgen Receptor Modulator

Half Life: About 4 hours

Formula: C19 H18 F3 N3 O6

Chemical Structure: S-3-(4-acetylamino-phenoxy)-2-hydroxy-2-methyl-N-(4-nitro-3-trifluoromethyl-phenyl)-propionamide

Anabolic Rating: Similar to Testosterone Propionate

Facts: Ostarine (*S-4) is a Selective Androgen Receptor Modulator produced by GTx Inc, which is currently in the investigational stages of development. A SARM is exactly what it sounds like: a compound (not an anabolic steroid) which has the ability to stimulate the androgen receptor (much the same way as anabolic steroids). Unfortunately, due to its status as a drug still in the developmental stage, most of the research on it has been done in rodents and trials only.

S-4 is an orally active (and highly bioavailable) selective agonist for androgen receptors which was shown to have anabolic effects in muscle and bone tissue. It has been shown to have no measurable effect on lutenizing hormone (LH) or follicle-stimulating hormone (FSH), but it has been shown to have some effect on prostate weight, with an androgenic potency around 1/3rd of its anabolic potency (1). Still, this is a good trade-off, because it’s anabolic effect has been measured to be roughly the same as testosterone. It has also been shown to produce dose-dependent increases in bone mineral density and mechanical strength in addition to being able decrease body fat and increase lean body mass (2).

Unfortunately, it has a short half-life in humans of only 4 hours (3), and thus far has only gone through phase II clinical testing in humans (4).

Practical Use: This compound has potential use for all aspects of male hormone replacement therapy, and could eventually replace testosterone for this purpose. Since there is currently no accepted test for SARMs, athletes who are subject to drug testing would find it to be a suitable replacement for anabolic steroid use. Since it doesn’t effect LH or FSH, it may also be a highly useful anabolic agent to be used while attempting post-cycle therapy.

Side Effects: Prostate enlargement (1/3rd of what is seen with testosterone) and potential acne are potential side effects, although most users don’t report either of them; much more common are vision problems (floaters, yellow-tinged vision). Water retention, gynecomastia, and most other steroid-related side effects are probably not possible. In addition, inhibition of natural hormone levels is probably minimal or nonexistent at worst.

Producing/Developing Company:

Ostarine by GTx Inc.

References:

The androgen receptor (′AR′″) is a ligand-activated transcriptional regulatory protein that mediates induction of male sexual development and function through its activity with endogenous androgens. Androgens are generally known as the male sex hormones. However, androgens also play a pivotal role in female physiology and reproduction. The androgenic hormones are steroids which are produced in the body by the testis and the cortex of the adrenal gland, or synthesized in the laboratory. Androgenic steroids play an important role in many physiologic processes, including the development and maintenance of male sexual characteristics such as muscle and bone mass, prostate growth, spermatogenesis, and the male hair pattern (Matsumoto, Endocrinol. Met. Clin. N. Am. 23:857-75 (1994). The endogenous steroidal androgens include testosterone and dihydrotestosterone (“DHT”) Testosterone is the principal steroid secreted by the testes and is the primary circulatiag androgen found in the plasma of males. Testosterone is converted to DHT by the enzyme 5 alpha-reductase in many peripheral tissues. DHT is thus thought to serve as the intracellular mediator for most androgen actions (Zhou, et al., Molec. Endocrinol. 9:208-18 (1995)). Other steroidal androgens include esters of testosterone, such as the cypionate, propionate, phenylpropionate, cyclopentylpropionate, isocarporate, enanthate, and decanoate esters, and other synthetic androgens such as 7-Methyl-Nortestosterone (“MENT′”) and its acetate ester (Sundaram et al., “7 Alpha-Methyl-Nortestosterone(MENT): The Optimal Androgen For Male Contraception,” Ann. Med., 25:199-205 (1993) (“Sundaram”)). Because the AR is involved in male sexual development and function, the AR is a likely target for effecting male contraception or other forms of hormone replacement therapy. The AR also regulates female sexual function (i.e., libido), bone formation, and erythropoiesis.

Worldwide population growth and social awareness of family planning have stimulated a great deal of research in contraception. Contraception is a difficult subject under any circumstances. It is fraught with cultural and social stigma, religious implications, and, most certainly, significant health concerns. This situation is only exacerbated when the subject focuses on male contraception. Despite the availability of suitable contraceptive devices, historically, society has looked to women to be responsible for contraceptive decisions and their consequences. Although health concerns over sexually transmitted diseases have made men more aware of the need to develop safe and responsible sexual habits, women still often bear the brunt of contraceptive choice. Women have a number of choices, from temporary mechanical devices such as sponges and diaphragms to temporary chemical devices such as spermicides. Women also have at their disposal more permanent options, such as physical devices like IUDs and cervical caps as well as more permanent chemical treatments, such as birth control pills and subcutaneous implants. However, to date, the only options available for men include the use of condoms or a vasectomy. Condom use, however is not favored by many men because of the reduced sexual sensitivity, the interruption in sexual spontaneity, and the significant possibility of pregnancy caused by breakage or misuse. Vasectomies are also not favored If more convenient methods of birth control were available to men, particularly long term methods that require no preparative activity immediately prior to a sexual act, such methods could significantly increase the likelihood that men would take more responsibility for contraception.

Administration of the male sex steroids (e.g., testosterone and its derivatives) has shown particular promise in this regard due to the combined gonadotropin-suppressing and androgen-substituting properties of these compounds (Steinberger et al, “Effect of Chronic Administration of Testosterone Enanthate on Sperm Production and Plasma Testosterone, Follicle Stimulating Hormones and Luteinizing Hormone Levels: A Preliminary Evaluation of a Possible Male Contraceptive”, Fertility and Sterility 28:1320-28 (1977)). Chronic administration of high doses of testosterone completely abolishes sperm production (azoospermia) or reduces it to a very low level (oligospermia). The degree of spermatogenic suppression necessary to produce infertility is not precisely known, However, a recent report by the World Health Organization showed that weekly intramuscular injections of testosterone enanthate result in azoospermia or severe oligospermia (i.e., less than 3 million sperm per ml) and infertility in 98% of men receiving therapy (World Health Organization Task Force on Methods Ar Regulation of Male Fertility, “Contraceptive Efficacy of Testosterone-Induced Azoospermia and Oligospermia in Normal Men,” Fertilily and Sterility 65:821-29 (1996)).

A variety of testosterone esters have been developed that are more slowly absorbed after intramuscular injection ancd, thus, result in greater androgenic effect. Testosterone enanthate is the most widely used of these esters. While testosterone enanthate has been valuable in terms of establishing the feasibility of hormonal agents for male contraception, it has several drawbacks, including the need for weekly injections and the presence of supraphysiologic peak levels of testosterone immediately following intramuscular injection (Wu, “Effects of Testosterone Enanthate in Normal Men: Experience From a Multicenter Contraceptive Efficacy Study,” Fertility and Sterility 65:626-36 (1996)).

“male drugs”. D. D. Miller, K. A. Veverka, and K. Chung report the large-scale synthesis of androgen-receptor modulators exemplified by 3a and 3b. These compounds have a variety of pharmaceutical applications related to male sex hormones, such as male contraceptives and drugs for treating prostate-related conditions. The inventors describe the kilogram-scale production of 3a and 3b by condensing 1 with 2a or 2b, as shown in Figure 1.

The reaction is carried out in the presence of a substantial excess of Cs2CO3 in THF. For the preparation of 3a, 6.17 mol Cs2CO3 is used with 3.37 mol 1; for 3b, 5.4 mol Cs2CO3and 2.7 mol 1 are used. (Disconcertingly, the patent shows the formula of the base as CsCO3, although the calculation of the molar amount is correct.) The preparation of 3atakes 3 h at 50 °C and is monitored by HPLC. TLC is used to monitor the synthesis of3b, which takes 8 h in refluxing THF.

To purify 3a, deionized water is added to an EtOH solution at room temperature to precipitate it; this process is repeated three times. The final yield of 3a is 83%. Purifying the product by using an alcohol and water is a key aspect of the patent and is covered in the claims. However, no analytical data are given to support the claimed purity. The workup of 3b also involves EtOH and water, but solvents EtOAc and MeO-t-Bu are also used; the product is isolated in 52% yield.

The inventors also describe the synthesis of compound 1 at kilogram scale (Figure 2). Acid chloride 5 is prepared by the reaction of carboxylic acid 4 with SOCl2. The acid chloride is not isolated, but it is treated with a solution of aniline derivative 6 and Et3N in THF over 3 h. After it is warmed to room temperature, the mixture is heated to 50 °C for 15 h. The reaction is monitored by TLC; 3.7 kg 1 is isolated by crystallization from warm toluene in 70.3% yield.

The multikilogram-scale synthesis of 4 is also described. The route, shown in Figure 3, starts with the preparation of compound 9 by simultaneously adding 4 M NaOH and a solution of acid chloride 8 in acetone to a mixture of carboxylic acid 7 and 4 M NaOH in acetone. The pH of the reaction mixture is kept at >10 by adding more 4 M NaOH as needed. Intermediate 9 is isolated by crystallization from MeO-t-Bu in 55.6% yield; it is then treated with N-bromosuccinimide (NBS) in DMF to cyclize it to 10. This is isolated in 87.7% yield by adding water to the reaction mixture. The final step is heating 10 to reflux in 24% aq HBr to produce 4, isolated as a crystalline solid from hot toluene in 81.3% yield.

The patent claims cover compounds related to 3a and 3b in which the nitro group is replaced by nitrile. Unfortunately, no examples are given describing the synthesis of these compounds. This is an efficient process for synthesizing 3a and 3b, and the inventors show that it is suitable for large-scale production. (University of Tennessee Research Foundation [Knoxville]. US Patent 7,968,721, June 28, 2011;

Novel pathway for the synthesis of arylpropionamide-derived selective androgen receptor modulator (SARM) metabolites of andarine and ostarine

TETRAHEDRON LETTERS,

Pages 2239-2242

Katharina M. Schragl, Guro Forsdahl, Guenter Gmeiner, Valentin S. Enev, Peter Gaertner

andexanet alfa

Portola gets FDA breakthrough therapy status for andexanet alfa

US-based biopharmaceutical firm Portola Pharmaceuticals has received breakthrough therapy designation from the US Food and Drug Administration (FDA) for its investigational Factor Xa inhibitor antidote, ‘andexanet alfa’.

read all at

Description

Key Characteristics

Potential Indications

Clinical Development

Phase 2 proof-of-concept studies are underway or planned. These randomized, double-blind, placebo-controlled studies are designed to assess the safety, tolerability, pharmacokinetics and pharmacodynamics of andexanet alfa after dosing of a direct/indirect Factor Xa inhibitor in healthy volunteers.

|

|

|---|---|

|

|

| Combination of | |

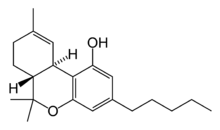

| Tetrahydrocannabinol | Cannabinoid |

| Cannabidiol | Cannabinoid |

GW Pharmaceuticals obtains Swiss approval for Sativex

GW Pharmaceuticals has received full marketing authorisation from the Swiss authorities for its prescription medicine Sativex to treat moderate to severe spasticity in multiple sclerosis (MS) patients who have not responded to other medications.

Nabiximols (USAN,trade name Sativex) is a patented cannabinoid oromucosal mouth spray developed by the UK company GW Pharmaceuticals for multiple sclerosis (MS) patients, who can use it to alleviate neuropathic pain, spasticity, overactive bladder, and other symptoms.Nabiximols is distinct from all other pharmaceutically produced cannabinoids currently available because it is a mixture of compounds derived fromCannabis plants, rather than a mono-molecular synthetic product. The drug is a pharmaceutical product standardised in composition, formulation, and dose, although it is still effectively a tincture of the cannabis plant. Its principal active cannabinoid components are the cannabinoids: tetrahydrocannabinol (THC) and cannabidiol (CBD). The product is formulated as an oromucosal spray which is administered by spraying into the mouth. Each spray delivers a near 1:1 ratio of CBD to THC, with a fixed dose of 2.7 mg THC and 2.5 mg CBD. Nabiximols is also being developed in Phase III trials as a potential treatment to alleviate pain due to cancer. It has also been researched in various models of peripheral and central neuropathic pain.

In May 2003 GW Pharmaceuticals and Bayer entered into an exclusive marketing agreement for GW’s cannabis-based medicinal extract product, to be marketed under the brand name Sativex. “Bayer has obtained exclusive rights to market Sativex in the UK. In addition, Bayer has the option for a limited period of time to negotiate the marketing rights in other countries in European Union and selected other countries around the world.”

In April 2011, GW licensed to Novartis the rights to commercialise nabiximols in Asia (excluding China and Japan), Africa and the Middle East (excluding Israel)

Of the two preliminary Phase III studies investigating the treatment of MS patients, one showed a reduction of spasticity of 1.2 points on the 0–10 points rating scale (versus 0.6 points under placebo), the other showed a reduction of 1.0 versus 0.8 points. Only the first study reached statistical significance. The Phase III approval study consisted of a run-in phase where the response of individuals to the drug was determined. The responders (42% of patients) showed a significant effect in the second, placebo controlled, phase of the trial.[10] A 2009 meta-analysis of six studies found large variations of effectiveness, with a trend towards a reduction of spasticity

Sativex® has now been launched in 11 countries (including the UK, Spain, Italy and Germany) with approvals in an additional 11 countries

PRANLUKAST

Antiasthmatic.

| Launched – 1995 japan150821-03-7, C27 H23 N5 O4 . H2O, 499.5179 |

103177-37-3 anhydrous, 103180-28-5 (monosodium salt)

Ono-1078

Ono-RS-411

RS-411

SB-205312

Ono-1070 (monosodium salt)

N-[4-Oxo-2-(1H-tetrazol-5-yl)-4H-1-benzopyran-8-yl]-4-(4-phenylbutoxy)benzamide hemihydrate

Ono (Originator)Schering-Plough (Licensee)

……….

J Med Chem 1988, 31(1): 84,

WO 2010002075,

Synth Commun 1997, 27(6): 1065,

WO 1994012492

Leukotriene antagonist.

Prepn: M. Toda et al., EP 173516; eidem, US 4780469 (1986, 1988 both to Ono);

H. Nakai et al., J. Med. Chem. 31, 84 (1988).

Pharmacology: T. Obata et al., Adv. Prostaglandin Thromboxane Leukotriene Res. 15, 229 (1985); idem et al., ibid. 17, 540 (1987).

Clinical evaluations in asthma: Y. Taniguchi et al., J. Allergy Clin. Immunol. 92, 507 (1993); H. Yamamoto et al. Am. J. Respir. Crit. Care Med. 150, 254 (1994).

AU 8546462; EP 0173516; JP 8650977; US 4780469; US 4939141

Pranlukast is a cysteinyl leukotriene receptor-1 antagonist. It antagonizes or reduces bronchospasm caused, principally in asthmatics, by an allergic reaction to accidentally or inadvertently encountered allergens.

Pranlukast is a cysteinyl leukotriene receptor-1 antagonist. This drug works similarly to Merck & Co.‘s Singulair (montelukast). It is widely used in Japan.

Medications of this class, which go under a variety of names according to whether one looks at the American, British or European system of nomenclature, have as their primary function the antagonism of bronchospasm caused, principally in asthmatics, by an allergic reaction to accidentally or inadvertently encountered allergens.

Medications of this group are normally used as an adjunct to the standard therapy of inhaled steroids with inhaled long- and/or short-acting beta-agonists. There are several similar medications in the group; all appear to be equally effective.

Toda synthetic complete with 3 – nitro-2 – hydroxyphenyl ko one for raw materials, ni ko with oxalic ester Claisen condensation occurs, and then heated to reflux for cyclization to construct benzo pyran ring; dehydrated by an amide synthesized ring cyano group, the cyano compound and then with sodium azide tetrazole synthesis. The nitro group on the compound in 5% Pd / C catalyzed hydrogenation of amino acid reacted with the compound Pranlukast held. This method directly using 4 – (4 – phenyl-butoxy)-benzoic acid reaction. Synthetic route is as follows:

[0006]

[0007]

[0008] ② Robert Graham and routes are routes to I-bromo-butane as a raw material, were used as a palladium catalyst, ligand compound formylation carbonylation reactions and condensation of potassium tert-butoxide, closed dehydration under acidic conditions benzopyran ring method. Synthetic route is as follows:

[0009] Robert routes:

[0010]

[0011] Graham route:

[0012]

[0013] The two synthetic routes are not disclosed in the I-Bromo butane feedstock pathway.

[0014] ③ Masayohi 2_ cyano synthetic route to a benzopyran derivative and hydrogen sulfide gas in the base-catalyzed addition reaction of 2 – thiocarbamoylbenzothiazol and pyran derivatives, and then were reacted with anhydrous hydrazine group hydrazone, with sodium nitrite under acidic conditions nitrosation reaction occurs tetrazole ring. Synthetic route is as follows:

[0015]

[0016] The materials used are not mentioned route synthesis method, it is only reflected in the improvement of the synthesis of the tetrazole ring.

[0017] ④ Giles, Hideki and Hayler are tetrazole substituent on the increase, making it easier condensation reaction, but the synthesis of substituted on the nitrogen with tetrazole difficult, and ultimately elimination reaction of lithium used tetrahydro aluminum and other hazardous reagents, is not easy to Eri industrialization. Reaction scheme is as follows:

[0018]

[0019] ⑤ Lee NK with 4_ (4_ Phenylbutoxy) benzonitrile and 2_ hydroxy _3_ iodobenzene ko 1H_4_ thiazolyl ketone and ester ko _5_ acid, concentrated sulfuric acid catalyzed cyclization iodide copper and potassium phosphate removal under the action of hydrogen iodide get Pranlukast held. Reaction scheme is as follows:

[0021] does not mention the route starting 4 – (4 – phenyl-butoxy)-benzonitrile synthesis method, while two – hydroxy – 3 – Synthesis of iodobenzene ko difficult one.

The synthesis method comprises the following steps: a. 4 – Synthesis of chlorobutanol THF was added concentrated hydrochloric acid, feeding the mass ratio of I: I. 389 ~ 5. 556,45-80 ° C was stirred for 5-18h, cooled, extracted with methylene chloride, removal of the solvent, distillation under reduced pressure to give 4 – chlorobutanol; b. 4 – phenyl butanol take benzene, aluminum chloride mixture ,0-25 ° C solution of 4 – chlorobutanol, reaction 5 -10h then poured into ice-water, a liquid, in addition to homogeneous solution U, distillation under reduced pressure, and the resulting colorless transparent liquid that is, 4 – phenyl butanol; c. I-bromo-4 – phenyl butane synthesis of 4 – phenyl butanol 40% hydrobromic acid mixture, feeding the mass ratio of I: 2. 857 ~ 11. 428, heat refluxing, cooling, liquid separation, the organic solvent divided by distillation under reduced pressure to give I-bromo-4 – phenyl butane; d. Synthesis of methyl p-hydroxybenzoate take-hydroxybenzoic acid and methanol, concentrated sulfuric acid and refluxed for 5-20h spin methanol, poured into cold water to precipitate a white solid which was filtered and dried to give the hydroxy benzoate; e. 4 – (4 – phenyl-butoxy)-benzoic acid methyl ester _ take I-bromo-4 – phenyl butane, DMF, toluene, methyl p-hydroxybenzoate and potassium carbonate, a reflux 5 ~ 20h, cooling water, extracted with toluene, light yellow liquid rotary evaporation, recrystallization, and the resulting white solid, that is, 4 – (4 – phenyl-butoxy) – benzoic acid methyl ester; f. 4 – (4 – phenyl-butoxy yl) – benzoic acid taken 4 – (4 – phenyl-butoxy) – benzoic acid methyl ester, 15% NaOH solution was refluxed for I ~ 5h, cooled, acidified, filtered and dried to give 4 – (4 – phenylbutyrate oxy) – benzoic acid; g. sprinkle bromophenyl acetic acid ester molar ratio Preparation of I: I ~ I. 5: O. I ~ I of bromophenol, acetic anhydride, pyridine feeding, reflux 3 ~ 10h, distilled pyridine, acetic acid and excess acetic anhydride distilled under reduced pressure to give the acetic acid esters bromophenol; h. 5 – bromo-2 – Preparation of light taken acetophenone molar ratio of I: I ~ 5: I of acetic acid bromophenol esters, aluminum chloride, tetrachlorethylene for feeding, reflux O. 5 ~ 5. 5h, cooled, the reaction solution was poured into 5% hydrochloric acid and extracted with methylene chloride, the solvent evaporated under reduced pressure, to obtain a gray crystalline 5 – bromo-2 – Light acetophenone; i. 5 – bromo-3 – nitro-2 – Preparation of light acetophenone take 5 – bromo-2 – Light acetophenone, carbon tetrachloride, 50 ~ 90 ° C is added dropwise nitric acid, reflux I ~ 4h, cooled, filtered, and the resulting yellow solid which is 5 – bromo-3 – nitro-2 – hydroxyacetophenone; j. 3 – amino-2 – Light benzene ethanone Preparation of 5 – bromo-3 – nitro-2 – hydroxyacetophenone, 5% Pd / C, methylene chloride, methanol, concentrated hydrochloric acid, water, hydrogenation; the end of the reaction mixture was filtered, the filtrate was The solvent was removed, neutralized with sodium bicarbonate, and the resulting yellow solid ginger i.e., 3 – amino-2 – hydroxyacetophenone; k. 3 – [4 - (4 - phenyl-butoxy)-benzoyl amino] -2 _ light base Preparation of acetophenone 4 – (4 – phenyl-butoxy)-benzoic acid, toluene, DMF, 45 ~ 105 ° C was added dropwise SOCl2, 30min the reaction liquid droplets to the 3 – amino-2 – hydroxyphenyl toluene solution of ethyl ketone, the reaction 3 ~ 10h, cooled, neutralized with dilute hydrochloric acid, extracted with toluene, rotary evaporation, and the resulting pale yellow crystals is 3 – [4 - (4_ phenylbutoxy) benzamido] 2_-hydroxyacetophenone; I. 2 – [4 - (4 - phenyl-butoxy)-benzoyl amino] -6 – [l, 3 - dioxo-3 - ethoxycarbonyl-propyl] phenol synthetic sodium, THF, 3 – [4 - (4 - phenyl-butoxy)-benzoyl amino]-2 – hydroxyacetophenone, diethyl oxalate 4 ~ IOh After stirring the reaction was poured into dilute hydrochloric acid to precipitate the yellow solid which was filtered, and the resulting product, i.e. 2 – [4 - (4_ phenylbutoxy) benzamido] _6_ [1,3 - dioxo-3 - ethoxy propyl intended yl] phenyl discretion ·; m. 4 – oxo-8 – [4 - (4 - phenyl-butoxy)-benzoyl amino]-2 – ethoxycarbonyl-4H-benzopyran take 2 – [4 - (4 - phenyl-butoxy yl) benzoyl amino] -6 – [l, 3 - dioxo-3 - ethoxycarbonyl-propyl] phenol, THF, force mouth heat, the addition of concentrated hydrochloric acid, refluxed for 8 ~ 15h, cooled, filtered, and the resulting white solid, that is, 4 – oxo-8 – [4 - (4 - phenyl-butoxy)-benzoyl amino]-2 – ethoxycarbonyl-4H-benzopyran; η. 4 – oxo-8 – [ 4 - (4 - phenyl-butoxy)-benzoyl amino] -2 – amino-carbonyl-4Η-benzopyran synthesis take four – oxo-8 – [4 - (4 - phenyl-butoxy)-benzoyl amino] -2 – ethoxycarbonyl-4Η-benzopyran was dissolved in DMF, and leads to dry ammonia gas, the reaction solution changed from yellow to red, the reaction solution was poured into cold water, adjusted to acidic, and filtered to give the product 4 – oxo-8 – [4 - (4 - phenyl-butoxy)-benzoyl amino] -2 – amino-carbonyl-4Η-benzopyran; P. 4 – oxo-8 – [4 - (4 - phenylbutoxy) benzamido] -2 – cyano-4Η-benzopyran take DMF, S0C12, 4 – oxo-8 – [4 - (4 - phenyl-butoxy)-benzoic amido] _2_ aminocarbonyl-4H-benzopyran, O ~ 15 ° C under stirring for 2 ~ IOh poured into cold water, filtered, and the resulting white solid that is, 4 – oxo-8 – [4 - (4 - phenylbutoxy) benzamido] -2 – cyano-4H-benzopyran; q. Synthesis of pranlukast take four – oxo-8 – [4 - (4 - phenyl-butoxy) benzoyl amino]-2_ cyano-4H-benzopyran, ammonium chloride, sodium azide, DMF, heating I ~ 8h then poured into ice-water, dilute hydrochloric acid, filtered, and the resulting white solid that the final product Pranlukast.

The reaction of ethyl 8-nitro-4-oxo-1-benzopyran-2-carboxylate (I) with ammonia in methanol gives the corresponding amide (II), which is dehydrated with POCl3 yielding 2-cyano-8-nitro-1-benzopyran-4-one (III). The cyclization of (III) with sodium azide by means of pyridinium chloride in hot DMF affords 8-nitro-2-(tetrazol-5-yl)-1-benzopyran-4-one (IV), which is hydrogenated with H2 over Pd/C in methanol – HCl giving 8-amino-2-(tetrazol-5-yl)-1-benzopyran-4-one (V). Finally, this compound is condensed with 4-(4-phenylbutoxy)benzoic acid (VI) by means of oxalyl chloride in dichloromethane-pyridine

254750-02-2 cas no

emricasan

PF 03491390, IDN 6556

pfizer

Prevention of fibrosis and inflammation in chronic liver disease

The compound had been studied in phase II clinical trials for the treatment of liver transplant rejection and hepatitis B

(3S)-3-[[(2S)-2-[[2-[(2-tert-butylphenyl)amino]-2-oxoacetyl]amino]propanoyl]amino]-4-oxo-5-(2,3,5,6-tetrafluorophenoxy)pentanoic acid, C26 H27 F4 N3 O7, 569.5

http://www.ama-assn.org/resources/doc/usan/emricasan.pdf

Conatus’s liver drug emricasan gets FDA orphan drug status

US-based biotechnology firm Conatus Pharmaceuticals has received orphan drug designation from the US Food and Drug Administration (FDA) for its drug candidate emricasan to treat liver transplant recipients with re-established fibrosis to delay the progression to cirrhosis and end-stage liver disease.http://www.pharmaceutical-technology.com/news/newsconatuss-chronic-liver-disease-treatment-emricasan-gets-fda-orphan-drug-status-4139697?WT.mc_id=DN_News

Emricasan, also known as IDN 6556 and PF 03491390, is a first-in-class caspase inhibitor in clinical trials for the treatment of liver diseases. IDN-6556 has marked efficacy in models of liver disease after oral administration and thus, is an excellent candidate for the treatment of liver diseases characterized by excessive apoptosis. IDN-6556 appears to be a feasible therapeutic agent against ischemia-reperfusion injury in liver transplantation.

WO 2002057298

WO 2000001666

Interleukin 1 (“IL-1″) is a major pro-inflammatory and immunoregulatory protein that stimulates fibroblast differentiation and proliferation, the production of prostaglandins, collagenase and phospholipase by synovial cells and chondrocytes, basophil and eosinophil degranulation and neutrophil activation. Oppenheim, J.H. et al.. Immunology Today, 7:45-56 (1986). As such, it is involved in the pathogenesis of chronic and acute inflammatory and autoimmune diseases. IL-1 is predominantly produced by peripheral blood monocytes as part of the inflammatory response. Mosely, B.S. et al.. Proc. Nat. Acad. Sci.. 84:4572-4576 (1987); Lonnemann, G. et al. Eur. J. Immunol., 19:1531-1536 (1989).

IL-lβ is synthesized as a biologically inactive precursor, proIL-lβ. ProIL-lβ is cleaved by a cysteine protease called interleukin-lβ converting enzyme (“ICE”) between Asp-116 and Ala-117 to produce the biologically active C-terminal fragment found in human serum and synovial fluid. Sleath, P.R. et al., J. Biol. Chem., 265:14526-14528 (1992); A.D. Howard et al, J. Immunol., 147:2964-2969 (1991).

ICE is a cysteine protease localized primarily in monocytes. In addition to promoting the pro -inflammatory and immunoregulatory properties of IL-lβ, ICE, and particularly its homologues, also appear to be involved in the regulation of cell death or apoptosis. Yuan, J. et al„ Cell, 75:641-652 (1993); Miura, M. et al. Cell, 75:653-660 (1993); Nett-Giordalisi, M.A. et al, J. Cell Biochem., 17B:117 (1993). In particular, ICE or ICE/ced-3 homologues are thought to be associated with the regulation of apoptosis in neurogenerative diseases, such as Alzheimer’s and Parkinson’s disease. Marx, J. and M. Baringa, Science, 259:760-762 (1993); Gagliardini, N et al„ Science, 263:826-828 (1994).

Thus, disease states in which inhibitors of the ICE/ced-3 family of cysteine proteases may be useful as therapeutic agents include: infectious diseases, such as meningitis and salpingitis; septic shock, respiratory diseases; inflammatory conditions, such as arthritis, cholangitis, colitis, encephalitis, endocerolitis, hepatitis, pancreatitis and reperfusion injury, ischemic diseases such as the myocardial infarction, stroke and ischemic kidney disease; immune-based diseases, such as hypersensitivity; auto-immune diseases, such as multiple sclerosis; bone diseases; and certain neurodegenerative diseases, such as Alzheimer’s and Parkinson’s disease. Such inhibitors are also useful for the repopulation of hematopoietic cells following chemo- and radiation therapy and for prolonging organ viability for use in transplantation.

ICE/ced-3 inhibitors represent a class of compounds useful for the control of the above-listed disease states. Peptide and peptidyl inhibitors of ICE have been described. However, such inhibitors have been typically characterized by undesirable pharmacologic properties, such as poor oral absorption, poor stability and rapid metabolism. Plattner, J.J. and D.W. Norbeck, in Drug Discovery Technologies, C.R. Clark and W.H. Moos, Eds. (Ellis Horwood, Chichester, England, 1990), pp. 92-126. These undesirable properties have hampered their development into effective drugs.

Accordingly, the need exists for compounds that can effectively inhibit the action of the ICE/ced-3 family of proteases, for use as agents for preventing unwanted apoptosis, and for treating chronic and acute forms of IL-1 mediated diseases such as inflammatory, autoimmune or neurodegenerative diseases. The present invention satisfies this need and provides further related advantages.

|

References |

1: McCall M, Toso C, Emamaullee J, Pawlick R, Edgar R, Davis J, Maciver A, Kin T, Arch R, Shapiro AM. The caspase inhibitor IDN-6556 (PF3491390) improves marginal mass engraftment after islet transplantation in mice. Surgery. 2011 Jul;150(1):48-55. doi: 10.1016/j.surg.2011.02.023. Epub 2011 May 18. PubMed PMID: 21596412.

2: Pockros PJ, Schiff ER, Shiffman ML, McHutchison JG, Gish RG, Afdhal NH, Makhviladze M, Huyghe M, Hecht D, Oltersdorf T, Shapiro DA. Oral IDN-6556, an antiapoptotic caspase inhibitor, may lower aminotransferase activity in patients with chronic hepatitis C. Hepatology. 2007 Aug;46(2):324-9. PubMed PMID: 17654603.

3: Hoglen NC, Anselmo DM, Katori M, Kaldas M, Shen XD, Valentino KL, Lassman C, Busuttil RW, Kupiec-Weglinski JW, Farmer DG. A caspase inhibitor, IDN-6556, ameliorates early hepatic injury in an ex vivo rat model of warm and cold ischemia. Liver Transpl. 2007 Mar;13(3):361-6. PubMed PMID: 17318854.

4: Baskin-Bey ES, Washburn K, Feng S, Oltersdorf T, Shapiro D, Huyghe M, Burgart L, Garrity-Park M, van Vilsteren FG, Oliver LK, Rosen CB, Gores GJ. Clinical Trial of the Pan-Caspase Inhibitor, IDN-6556, in Human Liver Preservation Injury. Am J Transplant. 2007 Jan;7(1):218-25. PubMed PMID: 17227570.

5: Poordad FF. IDN-6556 Idun Pharmaceuticals Inc. Curr Opin Investig Drugs. 2004 Nov;5(11):1198-204. Review. PubMed PMID: 15573871.

6: Hoglen NC, Chen LS, Fisher CD, Hirakawa BP, Groessl T, Contreras PC. Characterization of IDN-6556 (3-[2-(2-tert-butyl-phenylaminooxalyl)-amino]-propionylamino]-4-oxo-5-(2,3,5,6-te trafluoro-phenoxy)-pentanoic acid): a liver-targeted caspase inhibitor. J Pharmacol Exp Ther. 2004 May;309(2):634-40. Epub 2004 Jan 23. PubMed PMID: 14742742.

7: Valentino KL, Gutierrez M, Sanchez R, Winship MJ, Shapiro DA. First clinical trial of a novel caspase inhibitor: anti-apoptotic caspase inhibitor, IDN-6556, improves liver enzymes. Int J Clin Pharmacol Ther. 2003 Oct;41(10):441-9. PubMed PMID: 14703949.

8: Canbay A, Feldstein A, Baskin-Bey E, Bronk SF, Gores GJ. The caspase inhibitor IDN-6556 attenuates hepatic injury and fibrosis in the bile duct ligated mouse. J Pharmacol Exp Ther. 2004 Mar;308(3):1191-6. Epub 2003 Nov 14. PubMed PMID: 14617689.

9: Natori S, Higuchi H, Contreras P, Gores GJ. The caspase inhibitor IDN-6556 prevents caspase activation and apoptosis in sinusoidal endothelial cells during liver preservation injury. Liver Transpl. 2003 Mar;9(3):278-84. PubMed PMID: 12619025.

//////////////////////////////////////////////////////////

http://www.google.com/patents/WO2002057298A2

EXAMPLE 126

(3 S)-3 – [N-(N'-(2-TERT-BUTYLPHENYL)OXAMYL) ALANINYL] AMINO-5-(2′,3′,5′,6′-TETRAFLUOROPHENOXY)-4-OXOPENTANOIC ACID

Part A: [(N-Benzyloxycarbonyl Alaninyl]Aspartic Acid, β-tert-Butyl Ester

To a suspension of aspartic acid β-tert-butyl ester (3.784 g, 20 mmol) in dimethylformamide (150 mL) at room temperture under nitrogen was added bis(trimethylsilyl)-trifluoroacetamide (10.6 mL, 40 mmol). After stirring at room temperature for 30 min, the resulting clear solution was treated with (N- benzyloxycarbonyl)alanine N-hydroxysuccinimide ester (6.406 g, 20 mmol). After stirring at room temperature for an additional 48 hrs, the mixture was treated with water (20 mL), stirred for 15 min and then partitioned between EtO Ac/water. The organic phase was washed with water, 5% KHSO and saturated NaCl solutions, dried over anhydrous Na2SO and evaporated to a dryness. The residue was dissolved in Et2O and extracted with saturated NaHCO3. The aqueous extract was acidified (pH 2.0) with concentrated HCl and extracted with EtOAc. The EtOAc extract was washed with saturated NaCl solution, dried over anhydrous Na2SO4 and evaporated to a give the title compound (6.463 g, 82%) as a white foam. TLC(EtOAc-hexane-AcOH; 70:30:2) Rf = 0.50.

Part B: (3S,4RS -3-rAlaninynAmino-5-(2′.3′.5′.6′-TetrafluorophenoxyV4- Hydroxypentanoic Acid tert-Butyl Ester

Starting with [(N-benzyloxycarbonyl)alanmyl]aspartic acid, β-tert-butyl ester and following the methods described in Example 28, Parts B through E gave the title compound as a colorless, viscous oil. TLC(EtOAc-hexane; 1:1) Rf = 0.06.

Part C: (3 S,4RS -3-[ -(Η'-f2-tert-Butylρhenyl)Oxamyl) AlaninyllAmino-5- (2',3',5',6'-Tetrafluorophenoxy)-4-Hvdroxypentanoic Acid tert-Butyl

Ester

To a solution of N-(2-tert-butylphenyl)oxamic acid (0.041 g, 0.19 mmol, prepared from 2-tert-butylaniline by the method described in Example 1, Part A) in

CH C1 (6.0 mL) at 0°C under nitrogen was added hydroxybenzofriazole hydrate (0.030 g) followed by l-ethyl-3 -(3 ',3 '-dimethyl- l'-aminopropyl)- carbodiimide hydrochloride

(0.050 g, 0.26 mmol). After stirring at 0°C for 10 min, the mixture was treated with

(3S,4RS)-3-(alaninyl)amino-5-(2',3',5',6'-tetrafluorophenoxy)-4-hydroxypentanoic acid tert-butyl ester (0.079 g, 0.19 mmol) and N-methylmorpholine (22 μL, 0.20 mmol).

After stirring at room temperature for 16 hrs, the mixture was partitioned between EtOAc-water. The organic phase was washed with water, 5% KHSO , saturated

NaHCO3 and saturated NaCl solutions, dried over anhydrous Na2SO4 and evaporated to give the crude title compound (0.090 g, 77%) as a viscous oil. TLC(EtOAc-hexane;

1:1) Rf= 0.70.

Part D: r3S -3-rN-rN'-(2-tert-Butylphenyl Oxamyl)AlaninyllAmino-5- (2',3',5'.6'-Tetrafluorophenoxy)-4-Oxopentanoic Acid tert-Butyl Ester

To a solution of (3S,4RS)-3-[N-(N'-(2-tert-butylphenyl)oxamyl)alaninyl] amino-5-(2′,3′,5′36′-tetrafluorophenoxy)-4-hydroxypentanoic acid tert-butyl ester (0.0.092 g, ca 0.15 mmol) in CH2C1 (6.5 mL) at room temperature under nitrogen was added iodobenzene diacetate (0.188 g, 0.58 mmol) followed by a catalytic amount of 2,2,6,6-tetramethyl-l-piperidinyloxy free radical (TEMPO, 0.0046 g, 0.03 mmol). After stirring at room temperature for 16 hrs, the mixture was partitioned between EtOAc- water. The organic phase was washed with saturated NaHCO3 and saturated NaCl solutions, dried over anhydrous Na SO4 and evaporated to a dryness. The residue (0.096 g) was purified by preparative layer chromatography on silica gel eluting with EtOAc- hexane (3:7) to give the title compound (0.071 g, 77%) as a colorless glass. TLC(EtOAc-hexane; 2:3) Rf = 0.60.

Part E: (3S)-3-rN-(N’-r2-tert-Butylphenyl Oxamyl Alaninyl]Amino-5- (2′ ,3 ‘ , 5 ‘ ,6′ -Tetrafluorophenoxy)-4-Oxopentanoic Acid

To a solution of (3S)-3-[N-(N'-(2-tert- butylphenyl)oxamyl)alaninyl]amino-5-(2′,3′,5′,6′-tetrafluorophenoxy)-4-oxopentanoic acid, tert-butyl ester (0.071 g, 0.11 mmol) in CH2C12(2.5 mL)-anisole(0.05 mL) at room temperature under nitrogen was added trifluoroacetic acid (1.5 mL). The resulting clear solution was stirred at room temperature for 1 hr, evaporated to dryness and chased with toluene-CH2Cl2 (1:1). The residue (0.061 g) was purified by preparative layer chromatography on silica gel eluting with MeOH-CH2Cl2 (1:9) to give the title compound (0.044 g, 69%) as a colorless glass. MS(ES) for C26H27F4N3O7 (MW 569.51): positive 570(M+H); negative 568(M-H).

TRANDOLAPRIL

(2S,3aR,7aS)-1-[(2S)-2-{[(2S)-1-ethoxy-1-oxo-4-phenylbutan-2-yl]amino}propanoyl]-octahydro-1H-indole-2-carboxylic acid

87679-37-6 CAS NO

Indications. hypertention

Abbott..(opten , godrik, mavik), HOECHST MARION ROUSSEL..Odrik,

RU-44570, Preran,

Aventis Pharma (Originator), Nippon Roussel (Originator), Abbott (Licensee), Chugai (Licensee) Launched-1993

Launched-1993

Trandolapril is a non-sulhydryl prodrug that belongs to the angiotensin-converting enzyme (ACE) inhibitor class of medications. It is metabolized to its biologically active diacid form, trandolaprilat, in the liver. Trandolaprilat inhibits ACE, the enzyme responsible for the conversion of angiotensin I (ATI) to angiotensin II (ATII). ATII regulates blood pressure and is a key component of the renin-angiotensin-aldosterone system (RAAS). Trandolapril may be used to treat mild to moderate hypertension, to improve survival following myocardial infarction in clinically stable patients with left ventricular dysfunction, as an adjunct treatment for congestive heart failure, and to slow the rate of progression of renal disease in hypertensive individuals with diabetes mellitus and microalbuminuria or overt nephropathy.

Trandolapril is an ACE inhibitor used to treat high blood pressure, it may also be used to treat other conditions. It is marketed by Abbott Laboratories with the brand name Mavik.

Tarka is the brand name of an oral antihypertensive medication that combines a slow release formulation of verapamil hydrochloride, acalcium channel blocker, and an immediate release formulation of trandolapril, an ACE inhibtor. The patent, held by Abbott Laboratories, expires on February 24, 2015.

This combination medication contains angiotensin-converting enzyme (ACE) inhibitor and calcium channel blocker, prescribed for high blood pressure.

Trandolapril is a prodrug that is deesterified to trandolaprilat. It is believed to exert its antihypertensive effect through the renin-angiotensin-aldosterone system. Trandolapril has a half life of about 6 hours, and trandolaprilat has a half life of about 10. Trandolaprilat has about 8 times the activity of its parent drug. Approximately 1/3 of Trandolapril and its metabolites are excreted in the urine, and about 2/3 of trandolapril and its metabolites are excreted in the feces. Serum protein binding of trandolapril is about 80%.

Trandolapril is a drug that is used to lower blood pressure. Blood pressure is dependent on the degree of constriction (narrowing) of the arteries and veins. The narrower the arteries and veins, the higher the blood pressure. Angiotensin Il is a chemical substance made in the body that causes the muscles in the walls of arteries and veins to contract, narrowing the arteries and veins and thereby elevating blood pressure. Angiotensin Il is formed by an enzyme called angiotensin converting enzyme (ACE). Trandolapril is an inhibitor of ACE and blocks the formation of angiotensin Il thereby lowering blood pressure. The drop in blood pressure also means that the heart does not have to work as hard because the pressure it must pump blood against is less. The efficiency of a failing heart improves, and the output of blood from the heart increases. Thus, ACE inhibitors such as trandolapril are useful in treating heart failure.

Trandolapril‘s ACE-inhibiting activity is primarily due to its diacid metabolite, trandolaprilat, which is approximately eight times more active as an inhibitor of ACE activity.

……………………

synthesis

(3aR,7aS)-octahydroindole-2(S)-carboxylic acid (I) goes through the process of esterification with benzyl alcohol (II) in the presence of SOCl2 to produce the corresponding benzyl ester (III), and the yielding compound is then condensed with N-[1(S)-(ethoxycarbonyl)-3-phenylpropyl]-(S)-alanine (IV) in the presence of 1-hydroxybenzotriazole, N-ethylmorpholine and dicyclohexylcarbodiimide (DCC) in DMF to afford the benzyl ester (V) of the desired product. Lastly, the compound is debenzylated by hydrogenation with H2 over Pd/C in ethanol.

……………………………………………..

Trandolapril along with other related compounds was first disclosed in US4933361. The process for the synthesis of trandolapril was described in US4933361 and WO9633984.

US4933361 describes a process for the synthesis of trandolapril wherein the racemic benzyl ester of octahydro indole-2-carboxylic acid is reacted with N-[1-(S)-ethoxy carbonyl- 3- phenyl propyl]-L-alanine (ECPPA), to get racemic benzyl trandolapril, which is purified using column chromatography to get the 2S isomer of benzyl trandolapril, which is further debenzylated with Pd on carbon to get trandolapril as a foamy solid. This process has certain disadvantages, for example the product is obtained in very low yield. Purification is done using column chromatography, which is not suitable for industrial scale up.

WO9633984 discloses a process in which N-[1-(S)-ethoxy carbonyl-3- phenyl propyl]-L- alanine is activated with N-chlorosulfinyl imidazole, to get (N-[I-(S) N-[1-(S)-ethoxy carbonyl-3-phenyl propylj-L-alanyl-N-sulfonyl anhydride and which is further reacted with silyl-protected 2S,3aR,7aS octahydro indole 2-carboxyIic acid to obtain trandolapril. The main disadvantages of this process are that the silyl-protected intermediates are very sensitive to moisture, the process requires anhydrous conditions to be maintained and the solvent used has to be completely dried. It is very difficult to maintain such conditions on an industrial scale, and failing to do so leads to low yield of product.

The processes for preparing N-[1-(S)-ethoxy carbonyl-3-phenyl propyl]-L-alanine N- carboxyanhydride which is used in the process of the present invention are well known and are disclosed in JP57175152A, US4496541 , EP215335, US5359086 and EP1197490B1. Trans octahydro-IH-indole-2-carboxylic acid and its esters are the key intermediates in the synthesis of trandolapril. When synthesized, trans octahydro-1 H-indole-2-carboxylic acid is a mixture of four isomers, as shown below.

From the processes known in the prior art, trans octahydro-1 H-indole-2-carboxylic acid is converted to its ester and the ester is then either reacted directly with N-[1-(S)-ethoxy carbonyl-3-phenyl propyl]-L-alanine (ECPPA) and then the isomers are separated by column chromatography, or alternatively the ester is reacted with ECPPA followed by 0 deprotection. Trans octahydro-1 H-indole-2-carboxylic acid is always used in its protected form. No attempts have been made to resolve free trans octahydro-1 H-indole-2-carboxylic acid to convert it to the desired isomer (isomer D, above). Furthermore, none of the prior art processes is stereoselective, so resolution of the required isomer is required following condensation.

EP0088341 and US4490386 describe a method for the resolution of N-benzoyl (2RS,3aR,7aS) octahydro-1 H-indole-2-carboxylic acid using α-phenyl ethyl amine.

US6559318 and EP1140826 describe a process for the synthesis of (2S,3aR,7aS) 0 octahydro-1 H-indole-2-carboxylic acid using enzymatic resolution of its nitrile intermediate. Enzymatic resolution involves many steps and also requires column chromatography for purification making the process uneconomical industrially.

WO8601803 describes the preparation of (2S,3aR,7aS) octahydro-1 H-indole-2-carboxylic 5 acid ethyl ester and benzyl ester using 10-D-camphor sulphonic acid.

WO2004065368 describes the synthesis of (2S,3aR,7aS) octahydro-1 H-indole-2- carboxylic acid benzyl ester by resolution using 10-D-camphor sulphonic acid to prepare trandolapril. This process gives poor yields because the product has to be first resolved and then the ester is deprotected leading to further loss in yield, making the process low yielding and expensive.

W 02005/051909 describes a process for the preparation of trandolapril, i.e. (N-[I-(S)- carbethoxy-3-phenylpropyl}-S-alanyl-2S,3aR,7aS-octahydroindol-2-carboxyIic acid} as well as its pharmaceutical acceptable salts, using a racemic mixture of trans octahydroindole-2- carboxylic acid with the N-carboxyanhydride of {N-[1-(S)-ethoxycarbonyl-3-phenylpropyl}- S-alanyl (NCA) in a molar ratio of 1 :1 to 1.6:1 in a mixture of water and water-miscible solvent to obtain a mixture of diastereomers of trandolapril. The diastereomers are converted to salts which upon repeated crystallization from acetone and water, and reaction with a base gives pure trandolapril. Thus, the condensation reaction in the presence of water and a water-miscible solvent is not stereoselective.

The processes for preparing N-[1-(S)-ethoxy carbonyl-3- phenyl propyl]-l_-alanine N- carboxyanhydride starting from N-[1-(S)-ethoxy carbonyl-3- phenyl propyl]-L-alanine (ECPPA) are well known and are disclosed in JP57175152A, US4496541 , EP215335, US5359086 and EP1197490B1

The angiotensin-converting enzyme (ACE) inhibitor trandolapril is commonly prescribed as a cardiovascular drug for the control and management of mild to severe hypertension Chigh blood pressure) and may be used alone or in combination with diuretics or other antihypertensive agents. Administration of trandolapril is typically oral at a level of around 0.5-4 mg once a 15 day and may also be used in the management of conditions such as heart failure and left ventricular dysfunction following myocardial infarction.

Trandolapril itself is a prodrug, being converted to the acid form “trandolaprilat” in vivo. It is, however, • generally desirable to prepare and administer the ester form.. The structures of trandolapril and trandolaprilat ‘ are shown below.

Trandolapril Trandolaprilat

Various methods for the synthesis of trandolapril and related compounds have been proposed but each of these suffers from drawbacks . Frequently the syntheses require the use of dangerous reagents, which make industrial scale preparation hazardous and difficult and/or involve multiple steps resulting in a long and complex synthesis . One of the most important steps in the synthesis is the formation of the trans-fused octahydroindole ring, which is often difficult to separate from the cis-fused equivalent.

A number of the known synthetic routes to trandolapril proceed via the key intermediate (2S, 3aR,7aS) -octahydro,-lH-indole-2-carboxylic acid. This contains the key trans-fused octahydroindole ring and the correct stereochemistry for the carboxylic acid group at the 2-position. Frequently, these methods require the separation of the cis- and trans-fused rings and, in many cases, resolution of the carboxylate group at the 2 -position is necessary. Where production of the trans-fused ring junction has been possible without generating significant quantities of the cis-product, the syntheses have been long and/or required dangerous reagents such as mercury compounds.

(2S, 3aR, 7aS)-octahydro-lH-indole-2-carboxylic acid

US-A-4691022 gives a synthesis of the above intermediate compound in relatively few steps but requires the trans-octahydroindole as the starting material. The result is also a mixture of the 2-α and 2-β compounds.

EP-A-084164/US-A-4, 933,361 provides an apparently effective method for the synthesis of the cis-fused intermediate beginning with the high-pressure hydrogenation of indole at 100 atmospheres of hydrogen and a platinum catalyst. This document also provides two methods for forming the trans-fused octahydroindole ring, but neither is indicated as being efficient. The first method provides the stereochemistry for the 2 -position from substituted alanine, reacting this with activated cyclohexanone and cyclising the product to give a hexahydroindole . Unfortunately, the reduction of this hexahydroindole to the octahydro- compound produces both cis- and trans-fused product in unknown yield. The second method is to introduce the trans-ring via trans-octahydro-lH-quinolin-2 -one, but no indication of yield in the key step is given and complex series of halogenation, partial re-hydrogenation and re-arrangement are required to reach the desired intermediate .

WO 00/40555 / US 6559318 relies on enzymic resolution of a 2- (2 ‘ , 2 ‘ -methoxyethyl) cyclohexamine with Novozyme7 over 25 hours to provide the N-acetylated (1R, 2S) enantiomer which must then be separated by column chromatography from the. unreacted (IS, 2R) enantiomer. Neither the enzymic resolution nor the chromatography steps are well suited to industrial scale preparations. There are also around ten steps required to reach the desired compound.

The synthetic route to the above octahydroindole intermediate proposed by Henning et al . (Tett. Lett. 24(1983), 5343-5346) quickly and elegantly introduces a 1,2-trans configuration around a cyclohexane ring, but requires the use of mercuric nitrate. The use of mercury compounds is obviously undesirable in the preparation of pharmaceuticals. A further synthesis is provided by Brion et al . (Tett. Lett. 33 (1992) 4889-4892) but it is unclear whether they in fact prepare 5% or 95% of the desired product with 2S stereochemistry. In any case, the method requires eleven steps including an initial pig liver esterase digestion to provide the product in stereochemically pure form but in a 95:5 mixture of isomers at position 2. This method is thus complex and ill suited to industrial scale preparation.

ROUTE A – Separation of enantiomers by the formation of diastereomeric salts with a chiral resolving agent HA* (such as 0, O’ -dibenzoyl-L-tartaric acid), coupling with N- [1- (S) -ethoxycarbonyl-3-phenylpropyl] -L-alanine (ECPPA) derivative and finally deprotecting the carboxylic acid moiety Rλ (such as by hydrogenating a benzyl ester, where Rx = Bn) .

ROUTE B.- Direct reaction of 7A with ECPPA derivative that leads to the formation of diastereoisomers, deprotecting the carboxylic acid moiety and finally separation of diastereoisomers by conventional methods.

1) deprotection >■ trandolapril 2) separation of diastereoisomers

ROUTE C- Treatment of 7A in basic medium and deprotection that leads to the racemic mixture of octahydroindole acid followed by the reaction with ECPPA derivative. This will result in a diastereomeric mixture that can be separated by conventional methods.

COOEtCH,

,1 ) basic medium QC &° ‘ – trandolapril 2) deprotection

2) separation of

racemic diastereoisomers 7A 6C

Route D. Separation of isomers of 6C by conventional methods (i.e. formation of a diastereomeric salt) and coupling with ECCPA derivative.

trandolapril

Route E

This route is an inversion of the steps of route B Firstly the isomers are separated and then the protecting group is removed. 1) separation of diastereoisomers trandolapπl

racemic 2) deprotection

Route F. – The compound 8A is treated to remove the protecting grqup and coupled with an ECPPA derivative,

1) deprotection

2) base treatment

racemic 7A 8A

X activating group

………………………………………………………………………………

http://www.google.com/patents/US20060079698

…………..

INTERMEDIATE

(2S,3aR,7aS)-perhydroindole-2-carboxylic acid (42 g).

IR (Nujol, cm-1): 2923, 2854, 1600, 1458, 1377, 1319. 1H-NMR (D2O): δ 1.1-2.5 (m, 8H), 1.65(m,1H), 1.96-2.37 (m,2H), 2.91(td, 1H),4.46(d, 1H). Mass (m/z): 168.3(M-H).

http://www.faqs.org/patents/app/20110065930

(2S,3aR,7aS)-Octahydro-1H-indole-2-carboxylic acid hydrochloride

yield as a white solid.

1H NMR (D2O, 400 MHz): δ 4.42 (dd, 1H, J=11.1, 2.7 Hz), 2.93, (dt, 1H, J=11.8, 3.6 Hz), 2.36 (ddd, 1H, J=12.9, 6.7, 2.7 Hz), 2.31-2.16 (m, 1H), 2.11-2.01 (m, 2H), 1.92-1.90 (m, 1H), 1.79-1.75 (m, 1H), 1.68-1.53 (m, 2H), 1.34-1.13 (m, 3H);

LC-MS (m/z): 170.1 (M+H).sup.+. The isolated product (5) correlates to the material prepared according to U.S. Pat. No. 487,932 and Tetrahedron Lett., 1992, 33, 4889.

CAS No: 144540-75-0

……………………………………..

REF

Tan, X; He, W; Liu, Y (2009). “Combination therapy with paricalcitol and trandolapril reduces renal fibrosis in obstructive nephropathy”. Kidney international 76 (12): 1248–57. doi:10.1038/ki.2009.346. PMID 19759524.

Urbach, H., Henning, R., Teetz, V., Geiger, R., Becker, R. and Gaul, H. (Hoechst A.G.) Bicyclic amino acid derivatives.DE 3151690, EP 084164, EP 170775.JP 1989301659; JP 1989301695

……………………………………………………………………….

The ESI mass spectrum of the drug trandolapril displayed a molecular ion peak [M+H] + at 431.1 amu. The tandem mass spectra (MS2) showed the fragment ions at m/z 234.2, 170.2, 160.3, 134.2, 130.3, 117.2, 102.3 and 91

The IR spectrum of new impurity showed the following absorption bands 3277cm-1 (NH stretch), 2941cm-1 (aliphatic CH stretch), 1734 and 1653cm-1 (C=O) stretch and 1192cm-1 (C-O stretch)

1H NMR

13 C NMR

TRP = TRANDOLAPRIL COMPARED WITH 2 IMPURITIES

………………………………………………………………………………………

TRANDOLAPRIL SPECTRAL DATA

http://www.google.com.br/patents/US20060079698

IR (KBr, cm-1): 3444, 3280, 2973, 2942, 2881, 1735, 1654, 1456, 1367, 1193, 1024, 699.

The 1H-NMR (CDCl3): δ 7.2 (s, 5H), 4.4(m,4H), 4.2 (q,2H), 3.6-1.3 (m, 18H), 1.28(d+t,6H). CI Mass (m/z): 429.6(M-H).

……………………………………

United States Patent Application 20080171885

http://www.freepatentsonline.com/y2008/0171885.html

M.P.: 122-124° C.,

IR (KBr): 3278.7, 2942.2, 1735.2, 1654.3, 1456.7, 1433.7, 1366.5, 1192.8, 1101.5, 1063.8 and 1023.8 cm−1 (FIG. 1).

1H NMR (CD3OD, δ ppm): 7.33 (s, 5H), 4.34 (m, 3H), 3.86 (q, 2H), 3.28-1.46 (m, 17H) and 1.39 (d+t, 6H),

Mass (m/z, amu): 453.5 (M+Na) and 431.7 (M+H)+ molecular ion.

…………………………………………………………………………….

MORE INFO FOR READERS

trandolapril

Reaction of cyclohexene with acetonitrile and mercuric acetate followed by ligand exchange with sodium chloride gives the crystalline acetamidomercury chloride in 98% yield. Reaction of the product of formula XIIIa with α-chloro acrylonitrile followed by reaction with NaBH4 and ethanol gives the product of formula XIIIb, which is cyclized with sodium in DMF to get a mixture of Xlllc and XIIId in the ratio of 18.5 : 1. On hydrolysis, IIIa is obtained selectively.

In this method, cyclohexylamine derivative of formula-XXIX is resolved to produce enantiomerically pure product of formula XXX, which is converted to octahydroindole-2-carbonitrile of formula XXVIII a. The product of formula XXVIII a on hydrolysis yields the octahydroindole-2-carboxylic of formula III a.

Friday, 6 December 2013

AstraZeneca today announced that the European Commission (EC) has granted Marketing Authorisation to FluenzTM Tetra. Fluenz Tetra is a nasally administered four-strain live attenuated influenza vaccine for the prevention of influenza in children and adolescents from 24 months up to 18 years of age. The EC approval makes Fluenz Tetra the first and only intra-nasal four-strain influenza vaccine available in Europe.http://www.pharmalive.com/ec-approves-fluenz-tetra

WASHINGTON, Dec. 6, 2013 (AP) — Federal health officials have approved a highly anticipated hepatitis C drug from Gilead Sciences Inc. that is expected to offer a faster, more palatable cure to millions of people infected with the liver-destroying virus.

The Food and Drug Administration said Friday it approved the pill Sovaldi in combination with older drugs to treat the main forms of hepatitis C that affect U.S. patients.

Current treatments for hepatitis C can take up to a year of therapy and involve weekly injections of a drug that causes flu-like side effects. That approach only cures about three out of four patients. Sovaldi is a daily pill that in clinical trials cured roughly 90 percent of patients in just 12 weeks, when combined with the older drug cocktail.http://www.pharmalive.com/us-approves-breakthrough-hepatitis-c-drug

Product name: Sovaldi

Common name: Sofosbuvir

Alias: GS-7977, PSI-7977

Chinese name: Sophia Bouvet (Suofabuwei, cable release Wei)

CAS Registry Number :1190307 -88-0

The chemical structure

Indications: Chronic hepatitis C (HCV GT1, GT2, GT3, GT4)

Mechanism: nucleoside NS5B polymerase inhibitor

approved Time: December 6, 2013

, U.S. Patent Number: 7964580,8415322,8334270,7429572;, patent validity: March 26, 2029 (U.S. Patent No.: 7,964,580 and 8,334,270), April 3, 2025 (U.S. Patent No.: 7,429,572 and 8,415,322) Sales value (estimated): $ 1.9 billion (2014), 6600000000 USD (2016) Drug Companies: Gilead Sciences, Inc. (Gilead Sciences)

GS-7977, (S)-isopropyl 2-(((S)-(((2R,3R,4R,5R)-5-(2,4-dioxo-3,4- dihydropyrimidin^l(2H)-yl)-4-fluoro-3-hydroxy-4-methyltetrahydrofuran-2- yl)methoxy)(phenoxy)phosphoryl)amino)propanoate, available from Gilead Sciences, Inc., is described and claimed in U.S. Patent No. 7,964,580. (See also US 2010/0016251, US 2010/0298257, US 201 1/0251 152 and US 2012/0107278.) GS-7977 has the structure:

GS-7977 can be crystalline or amorphous. Examples of preparing crystalline and amorphous forms of GS-7977 are disclosed in US 2010/0298257 (US 12/783,680) and US 201 1/0251 152 (US 13/076,552), both of which are incorporated by reference.

…………

Tandospirone, [112457-95-1]

US 5011841

(lR*,2S*,3R*,4S*)-N-[4-[4-(2- US 5011841 citrate Pyrimidinyl) piperazin-1-

yl] butyl ] -2 , 3-norbornane- dicarboximide citrate

Tandospirone hyd, SM-3997,

Chemical Name: (3aR,4S,7R,7aS)-rel-Hexahydro-2-[4-[4-(2-pyrimidinyl)-1-piperazinyl]butyl]-4,7-methano-1H-isoindole-1,3(2H)-dione hydrochloride

Tandospirone (Sediel), also known as metanopirone, is an anxiolytic andantidepressant used in China and Japan, where it is marketed by Dainippon Sumitomo Pharma. It is a member of the azapirone and piperazine chemical classes and is closely related to other agents like buspirone and gepirone.

Tandospirone is most commonly used as a treatment for anxiety and depressive disorders, such as generalised anxiety disorder and dysthymia respectively.[1] For both indications it usually takes a couple of weeks for therapeutic effects to be start being seen,[1] although at higher doses more rapid anxiolytic responses have been seen.[2] It has also been used successfully as a treatment for bruxism.[3]

Tandospirone has also been tried, successfully, as an adjunctive treatment for cognitive symptoms in schizophrenic individuals.[4]

It is not believed to be addictive but it is known to produce mild withdrawal effects (e.g. anorexia) after abrupt discontinuation.[1]

Yevich, Joseph P.; New, James S.; Smith, David W.; Lobeck, Walter G.; Catt, John D.; Minielli, Joseph L.; Eison, Michael S.; Taylor, Duncan P. et al. (1986). “Synthesis and biological evaluation of 1-(1,2-benzisothiazol-3-yl)- and (1,2-benzisoxazol-3-yl)piperazine derivatives as potential antipsychotic agents”. Journal of Medicinal Chemistry 29 (3): 359–69. doi:10.1021/jm00153a010.PMID 2869146.